Imikhiqizo

-

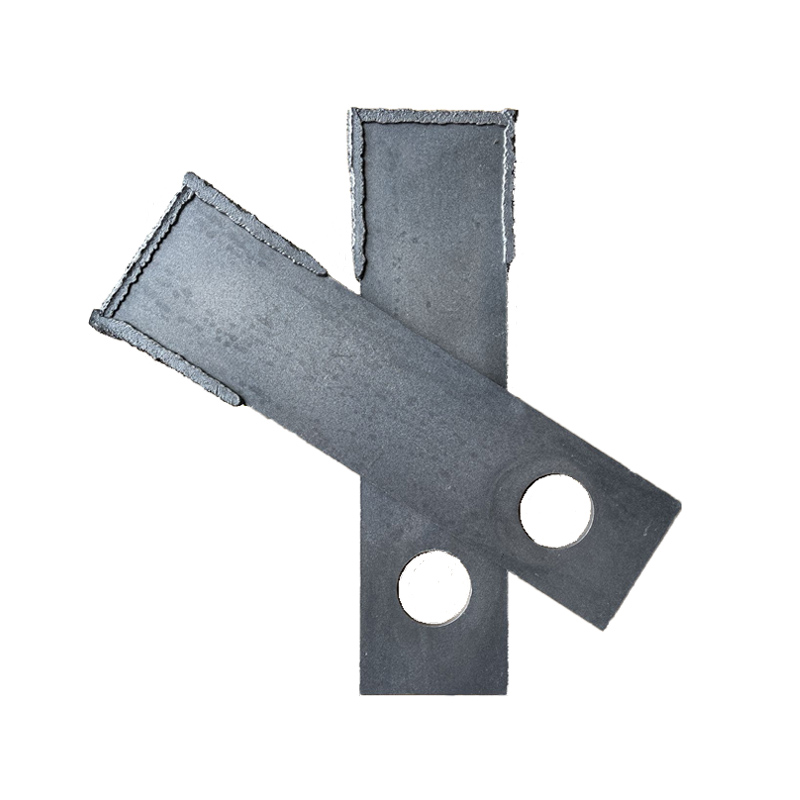

I-Tungsten Carbide Overlay Welding Hammer Blade

Sihlinzeka ngezinsimbi zokushisela ze-tungsten carbide ezinokuqina okuphezulu kakhulu, ukumelana nokugqokwa okuqinile, nempilo ende yesevisi. Zisebenza ngokwethembeka ezindaweni ezinokhahlo futhi zilungele izimboni ezinzima.

-

Izinhlayiya Zokusebenza ze-Tungsten Carbide Welding Technology ku-Shear Vulnerable Parts

Ikwazi ukumelana nokugqokwa okuphezulu, ukumelana nokushayisana okukhulu, ukuklebhuka okucijile.

-

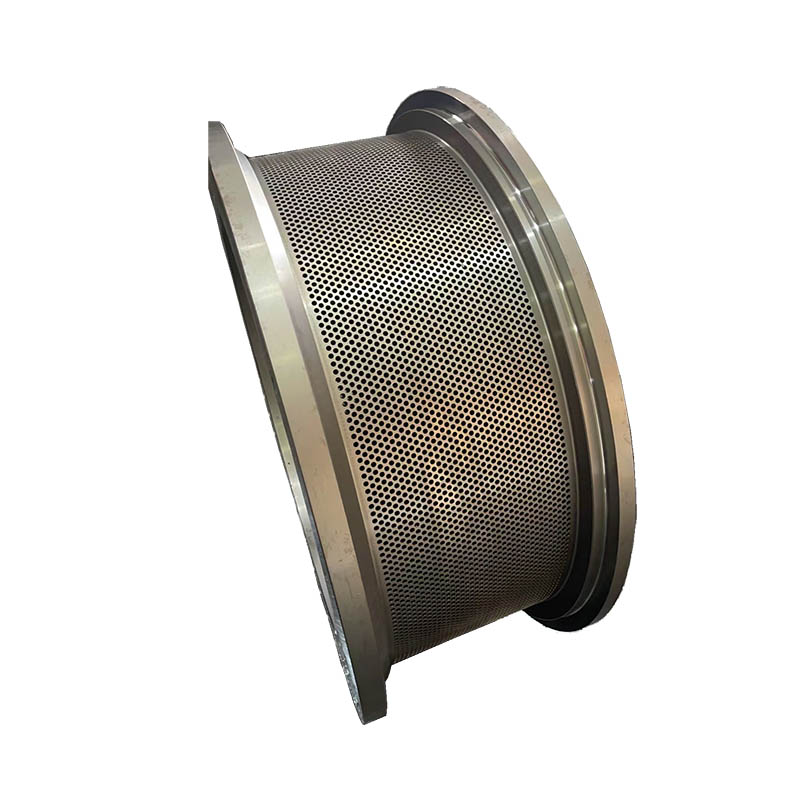

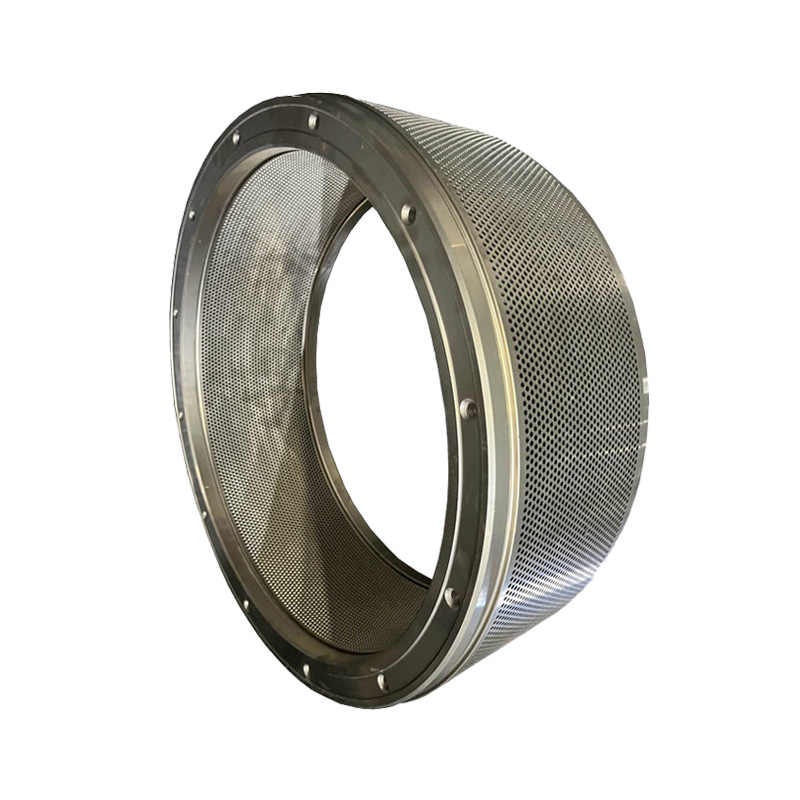

Ring Die

Singahlinzeka ngokufa kweringi kuzo zonke izinhlobo eziyinhloko zomshini we-pellet njenge-CPM, i-Buhler, i-CPP, ne-OGM. Ubukhulu obungokwezifiso kanye nemidwebo yama-ring dies wamukelekile.

-

I-Crab Feed Pellet Mill Ring Die

I-ring die inamandla amahle okuqina, ukugqwala okuhle kanye nokumelana nomthelela. Ukuma nokujula kwe-die hole kanye nezinga lokuvula imbobo kuqinisekisiwe ukuhlangabezana nezidingo ezahlukene ze-aquafeed.

-

Inhlanzi Okuphakelayo Pellet Mill Ring Die

Ukusatshalaliswa kwembobo ye-ring die iyunifomu. Inqubo ethuthukisiwe yokwelapha ukushisa kwe-vacuum, gwema i-oxidation yezimbobo zokufa, qinisekisa ngempumelelo ukuqedwa kwezimbobo zokufa.

-

Izinkukhu kanye Nemfuyo Okuphakelayo Pellet Mill Ring Die

Le ringi yokugaya ilungele ukugaywa kwezinkukhu nokudla kwemfuyo. Inesivuno esikhulu futhi ikhiqiza ama-pellets akhiwe kahle, anomthamo omkhulu.

-

Izinkomo Nezimvu Okuphakelayo Pellet Mill Ring Die

I-ring die yenziwe nge-alloy ye-chrome ephezulu, ebhobozwe ngezibhamu ezikhethekile ze-deep-hole futhi ifakwe ukushisa ngaphansi kwe-vacuum.

-

I-Flat Die yomshini wePellet

I-HAMMTECH inikezela ngezinhlobonhlobo zamafulethi ezifa ezinosayizi abahlukahlukene namapharamitha. Ifa lethu eliyisicaba linezakhiwo ezinhle zemishini nempilo ende yesevisi.

-

I-Tungsten Carbide Hammer Blade Enembobo Eyodwa

Izindwani zesando ze-Tungsten carbide zivame ukuklanywa ngezici ezivimbela ukudlidliza ezisiza ukunciphisa inani lokushaqeka nokudlidliza okudluliselwa esandleni nengalo yomsebenzisi ngesikhathi sokusetshenziswa.

-

I-Tungsten Carbide Hammer Blade enezimbobo ezimbili

Ukuqina nokuminyana kwe-tungsten carbide kuyivumela ukuthi idlulisele amandla engeziwe entweni eshaywayo, okungakhuphula amandla omthelela wensimbi yesando.

-

I-Single Hole Smooth Plate Hammer Blade

Le blade yesando yepuleti ebushelelezi eyenziwe ngensimbi yezinga eliphezulu eqinile ingamelana nokusetshenziswa kanzima nomthelela ngaphandle kokuphuka noma ukugoba.

-

Igobolondo Lamazinyo Eliqondile

Igobolondo le-roller elivulekile elinamazinyo aqondile livumela ukususwa kalula nokushintshwa kwama-roller.