I-Tungsten Carbide Hammer Blade Enembobo Eyodwa

Ukuqina kwendawo

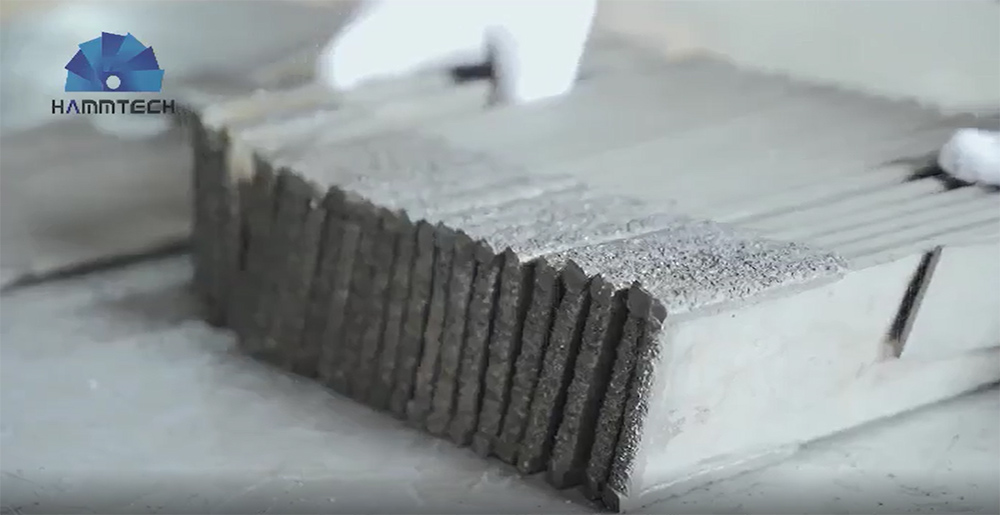

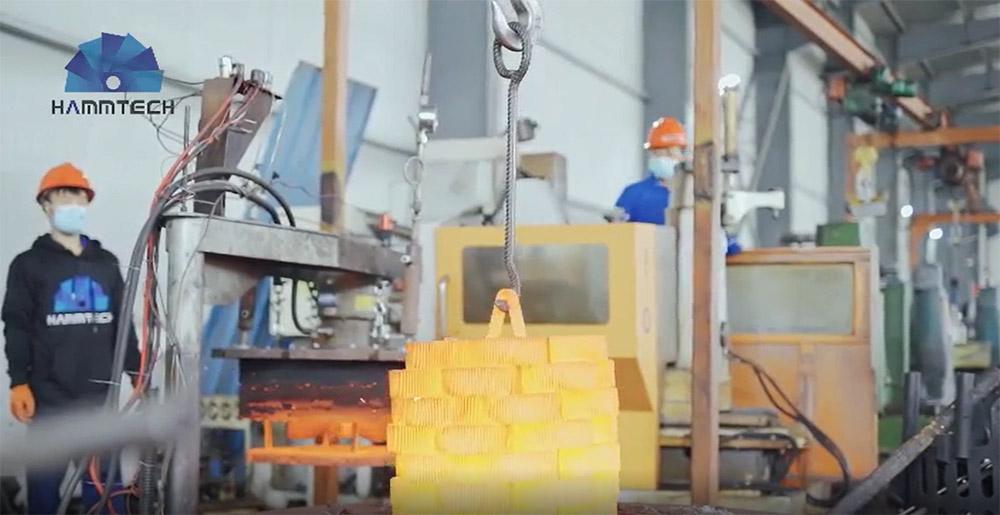

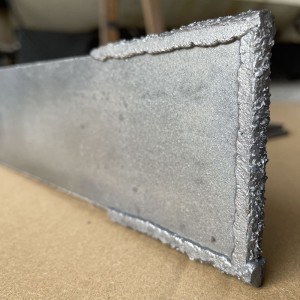

Ingxubevange ye-tungsten carbide imbozwe emaphethelweni okusebenza kwesando, enogqinsi oluyi-1 kuya ku-3 mm.Ngokwemiphumela yokuhlolwa, impilo yesevisi yezinsimbi zesando ezishiselwe we-tungsten carbide alloy iphakeme ngokuphindwe ngo-7~8 kunaleyo yama-sando acishiwe angu-65Mn iyonke, kodwa izindleko zokukhiqiza zangaphambili ziphezulu ngokuphindwe kabili.

Ukunemba Kwemishini

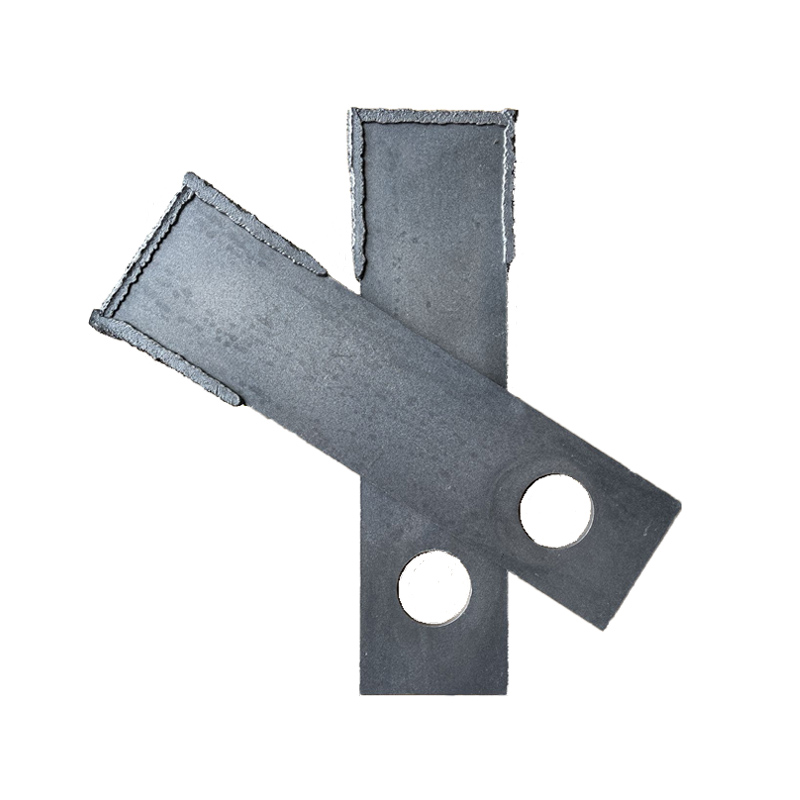

Isando siyingxenye egijima ngesivinini esikhulu, futhi ukunemba kwayo kokukhiqiza kunethonya elikhulu ebhalansi ye-pulverizer rotor.Ngokuvamile kuyadingeka ukuthi umehluko omkhulu phakathi kwanoma yimaphi amaqembu amabili esando ku-rotor akufanele udlule i-5g.Ngakho-ke, ukunemba kwesando kufanele kulawulwe ngokuqinile phakathi nenqubo yokucubungula, ikakhulukazi ngokubeka izando ze-tungsten carbide, ikhwalithi yenqubo yokubeka phezulu kufanele iqinisekiswe ngokuqinile.Ama-hammer blade kufanele afakwe ngamasethi, futhi ukushintshana okungahleliwe phakathi kwamasethi akuvunyelwe.

Ubuningi Nokuhlela

Inombolo nokuhlelwa kwezinhlamvu zesando ku-rotor yesigayo sesando kuthinta ibhalansi ye-rotor, ukusatshalaliswa kwezinto ezisegunjini lokuchoboza, ukufana kokugqoka isando, nokusebenza kahle kwesigxobo.

Inani lama-hammer blades likalwa ngenani lezindwani zesando ngeyunithi ngayinye yobubanzi be-rotor (ukuminyana kwesando), ukuminyana kukhulu kakhulu ukuze i-rotor iqale i-torque, impahla ishaywa izikhathi eziningi, futhi ukuphuma kwe-kWh kuncishisiwe;ukuminyana kuncane kakhulu ukuthi okuphumayo kwe-crusher kuzothinteka.

Ukuhlelwa kwezinhlamvu zesando kubhekisela ebudlelwaneni bendawo ehlobene phakathi kwamaqembu ama-sando blades ku-rotor naphakathi kweqembu elifanayo lama-sando.Ukuhlelwa kwezintambo zesando kungcono kakhulu ukufeza izidingo ezilandelayo: lapho i-rotor ijikeleza, i-trajectory ye-hammer blade ngayinye ayiphindi;impahla ayishintshi ohlangothini olulodwa ekamelweni lokuchoboza ngaphansi kwezinsimbi zesando (ngaphandle kwezidingo ezikhethekile);i-rotor ilinganisela ngokwamandla futhi ayidlidlizi ngesivinini esikhulu.

Isimiso Sokusebenza

Iqembu lama-sando blades lizungeza ngokusebenzisa amandla, futhi ngemva kokufinyelela isivinini esithile, impahla efakwe emshinini izochotshozwa (inkulu ephukile encane), futhi ngaphansi kwesenzo se-fan, into echotshoziwe izokhishwa emshinini izimbobo zesikrini.

Ukushintshwa Komkhiqizo

I-hammer blade iyingxenye esebenzayo ye-crusher eshaya ngokuqondile okokusebenza, ngakho-ke iyona egqokwa eshesha kakhulu futhi eshintshwa kaningi.Lapho ama-engeli amane okusebenza ama-hammer blades esegugile, kufanele ashintshwe ngesikhathi.