Imikhiqizo

-

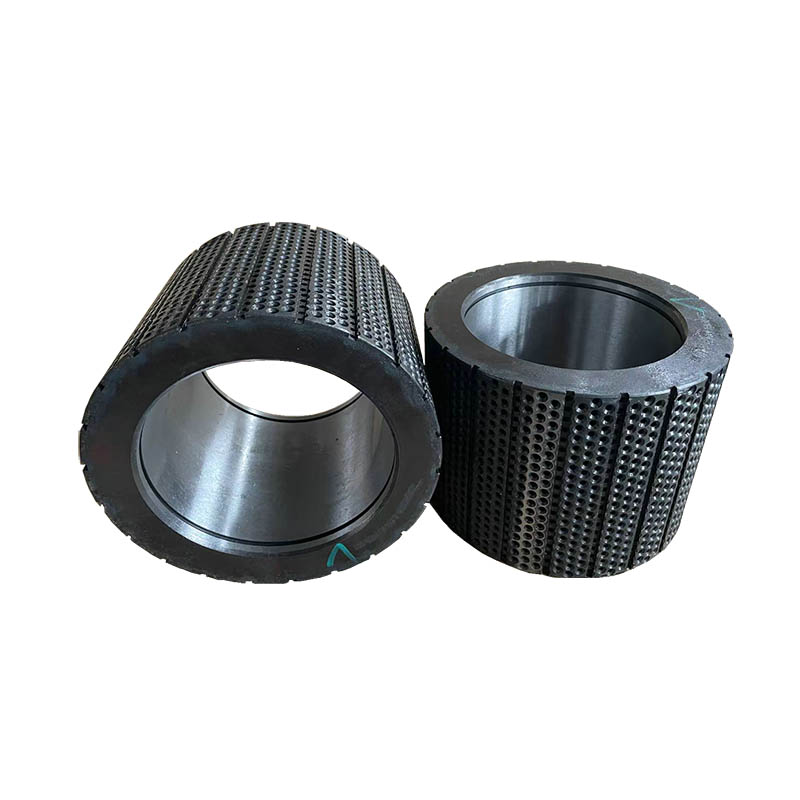

Igobolondo le-Dimpled Roller lomshini wePellet

Leligobolondo le-roller lithatha inqubo entsha yokwengeza amazinyo embobo emazinyweni aqondile wawo wonke umzimba wegobolondo le-roller.Uhlobo lwamazinyo amabili inhlanganisela edidiyelwe.Inqubo yokwelapha ukushisa okwesibili.Kuthuthukise kakhulu ubulukhuni nokumelana nokugqoka kwegobolondo le-roller.

-

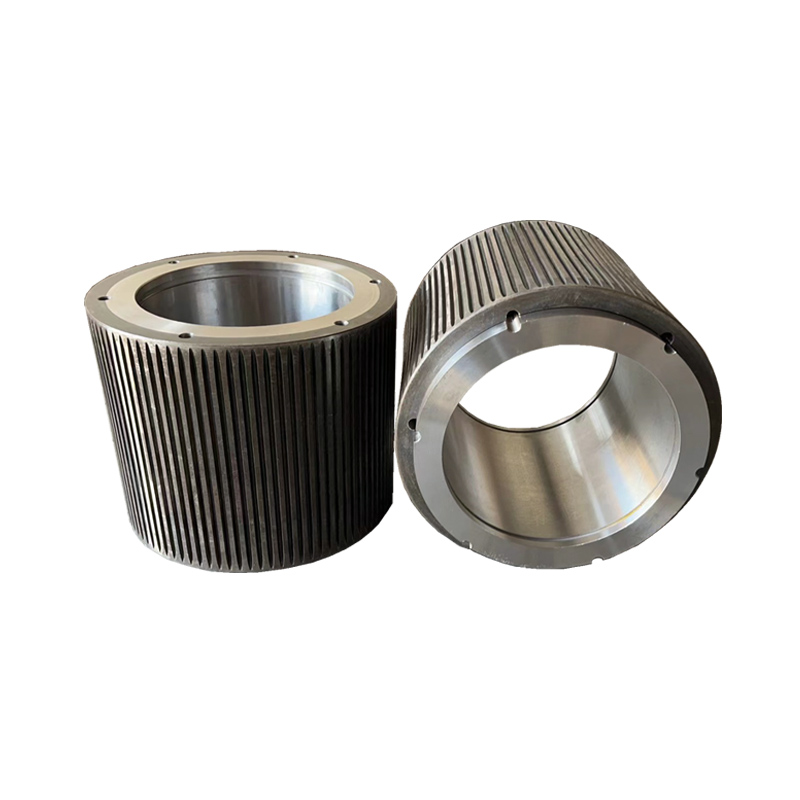

Igobolondo Eliyisiphetho Elivaliwe le-Pellet Mill

Ubuchwepheshe bomhlaba bokuqala nobuqanjwe kabusha.Isendlalelo sangaphandle segobolondo le-pressure roller singasuswa futhi sishintshwe, futhi isendlalelo sangaphakathi singasetshenziswa kabusha, silondoloze izindleko zokusetshenziswa nokudala inani elingeziwe.

-

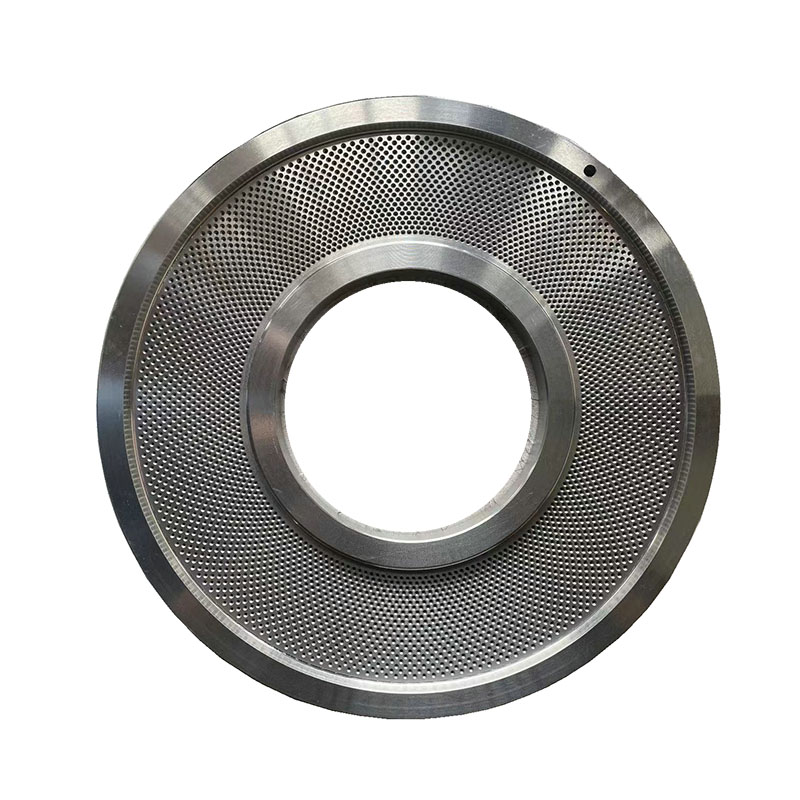

Biomass kanye Nomanyolo Pellet Mill Ring Die

• Insimbi ye-alloy yekhwalithi ephezulu noma insimbi engagqwali

• Ukwakhiwa okunembe ngokwedlulele

• Ukuqina okuphezulu ngemva kokwelashwa kokushisa

• Ihlala isikhathi eside ngenxa yomthelela ophezulu, ingcindezi, nezinga lokushisa

-

I-Shrimp Feed Pellet Mill Ring Die

1. Impahla: X46Cr13 /4Cr13(insimbi engagqwali), 20MnCr5/20CrMnTi (insimbi yengxubevange) eyenziwe ngokwezifiso

2. Ukuqina: HRC54-60.

3. Ububanzi: 1.0mm kufika ku-28mm; Ububanzi bangaphandle: kufika ku-1800mm.

Singakwazi ukwenza ngokwezifiso ama-ring ahlukene ezinhlobo eziningi, njengeCPM, Buhler, CPP, kanye ne-OGM. -

Umkhiqizi Wezesekeli ze-Hammermill kanye Nezesekeli ze-Pelletmill

I-Changzhou Hammermill Machinery Technology Co., Ltd. (HAMMTECH) iyimboni egxile ekukhiqizeni izingxenye ezisele zemishini yokuphakelayo.Singakwazi ukukhiqiza igiya elikhulu kanye negiya elincane le-pellet mill ehlukahlukene, i-hoop die clamp, umkhono we-spacer, shaft yegiya, nezinhlobo ezahlukenei-ring die, igobolondo le-roller, i-roller shell shaft, kanye nokuhlanganiswa kwegobolondo lama-roller ngokuya ngemidwebo yekhasimende.

-

I-Tungsten Carbide Sawdust Hammer Blade

Le blade yesando ye-tungsten carbide esetshenziselwa ukugaya izinkuni yenziwe nge-alloy ephansi engu-65 manganese njengesisekelo, enobulukhuni obuphezulu kanye ne-tungsten carbide overlay welding kanye nokuqiniswa kwe-welding, okwenza ukusebenza komkhiqizo kube ngcono nangaphezulu.

-

I-Tungsten Carbide Blade ye-Sugar Cane Shredder Cutter

Lolu hlobo lwe-tungsten carbide blade luthatha i-alloy eqinile enezakhiwo ezinjengokuqina okuphezulu, ukumelana nokugqoka kanye nokumelana nokugqwala okuphezulu.Kuyasiza ukwenza ukushwaqa umoba kusebenze kahle.

-

I-3MM Tungsten Carbide Hammer Blade

Singakhiqiza izindwani zesando ze-tungsten carbide ezinosayizi abahlukene.Akhiqizwe ngensimbi efojiwe yekhwalithi ephezulu futhi yaqedwa ngobuchwepheshe obuqinile bobuso obuqinile, ama-sando ethu aklanyelwe ukuhlangabezana nezinhlelo zokusebenza ezidingeka kakhulu.

-

I-Double Hole Smooth Plate Hammer Blade

I-hammer blade iyingxenye ebaluleke kakhulu yokugaya isando.Igcina ukusebenza kahle kwesigayo sesando, kodwa futhi iyingxenye eguga kakhulu.Izindwani zethu zesando zenziwe ngensimbi ye-carbon enamandla kakhulu futhi zenzelwe izinhlelo zokusebenza ezidinga kakhulu ngobuchwepheshe be-hardfacing obuhamba phambili embonini.

-

I-Pellet Mill Flat Die

Okubalulekile

Uhlobo lwensimbi olusetshenziselwa ukukhiqiza luyisici esibalulekile ekuqineni komkhiqizo wokugcina.Insimbi ye-alloy ekwazi ukumelana nokugqokwa kwekhwalithi ephezulu enokumelana nokugqokwa okuphezulu nokuqina kuyokhethwa, okuhlanganisa i-40Cr, 20CrMn, insimbi engagqwali, njll. -

I-Pneumatic Conveying System

I-positive pressure dense phase pneumatic conveying system isebenzisa umoya ocindezelwe njengendlela yokudlulisa.Epayipini, izinto ezisetshenziswayo zithuthwa ngesivinini esiphansi, isimo sendunduma yesihlabathi, i-fluidization noma isimo se-agglomeration, esibizwa ngokuthi i-positive pressure dense phase transportation pneumatic.