Igobolondo Lamazinyo Eliqondile

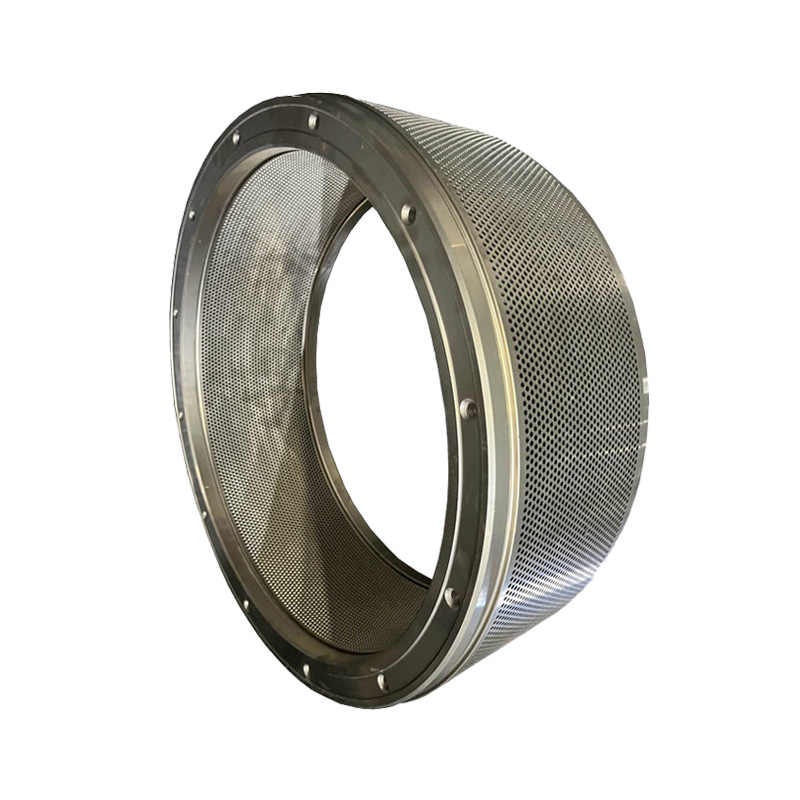

Igobolondo le-pellet mill roller luhlobo lwezingxenye zokugqoka ezidinga ukushintshwa uma kunesidingo. Ukuze sinwebe impilo yayo yesevisi, kufanele silandele izinyathelo ezingezansi ukuze sifunde ukuyinakekela.

1. Hlanza igobolondo le-roller njalo ngebhulashi noma umoya ocindezelwe ukususa uthuli nemfucumfucu.

2. Hlola igobolondo lamarola ukuze uthole noma yiziphi izimpawu zokuguga noma zokulimala. Uma kukhona umonakalo, shintsha igobolondo le-roller ngokushesha ngangokunokwenzeka.

3. Ukugcoba ngendlela efanele kubalulekile ekusebenzeni kahle kwesigayo se-pellet kanye negobolondo le-roller. Gcoba igobolondo le-roller nama-bearings nge-lubricant efanele, ngokusho kwezincomo zomenzi.

4. Hlola ukuqina kwegobolondo le-roller njalo. Uma ixega, ilungise ifike endaweni efanele.

5. Ukushisa komshini we-pellet kufanele kuqashelwe futhi kulawulwe ukuvimbela ukushisa, okungalimaza igobolondo le-roller. Landela izincomo zomkhiqizi zokulawula izinga lokushisa.

6. Khetha izinto ezifanele zegobolondo le-roller ngokusekelwe ohlotsheni lwezinto ezicutshungulwayo. Isibonelo, izinto eziqinile zidinga amagobolondo ama-roller ahlala isikhathi eside.

7. Ukuqeqeshwa okufanelekile komqhubi kubalulekile ekusebenzeni okuphephile nokusebenza kahle kwesigayo se-pellet. Ukuqinisekisa ukuthi opharetha baqeqeshiwe mayelana nezinqubo ezifanele zokusebenza kanye nokulungisa.

1. Gwema ukulayisha ngokweqile isigayo se-pellet. Ukulayisha ngokweqile kungabangela ukuguga nokudabuka ngokweqile kugobolondo le-roller, okuholela ekuhlulekeni kwalo ngaphambi kwesikhathi.

2.Ungalokothi usebenzise igobolondo elimele. Kungabangela umonakalo emshinini we-pellet futhi kuholele ezimweni ezingaphephile.

3. Qinisekisa ukuthi isigayo se-pellet sivaliwe ngaphambi kwanoma yikuphi ukulungiswa noma ukuhlanzwa.

4. Njalo gqoka izinto zokuzivikela ezifanele njengamagilavu, izibuko, nokuvikela indlebe ukuze ugweme noma yiziphi izingozi.

5. Ngaso sonke isikhathi bheka imanuwali yomkhiqizi ukuze uthole iziyalezo eziqondile mayelana nokugcinwa nokusetshenziswa kahle kwesigayo se-pellet.