Igobolondo le-Circle Teeth Roller

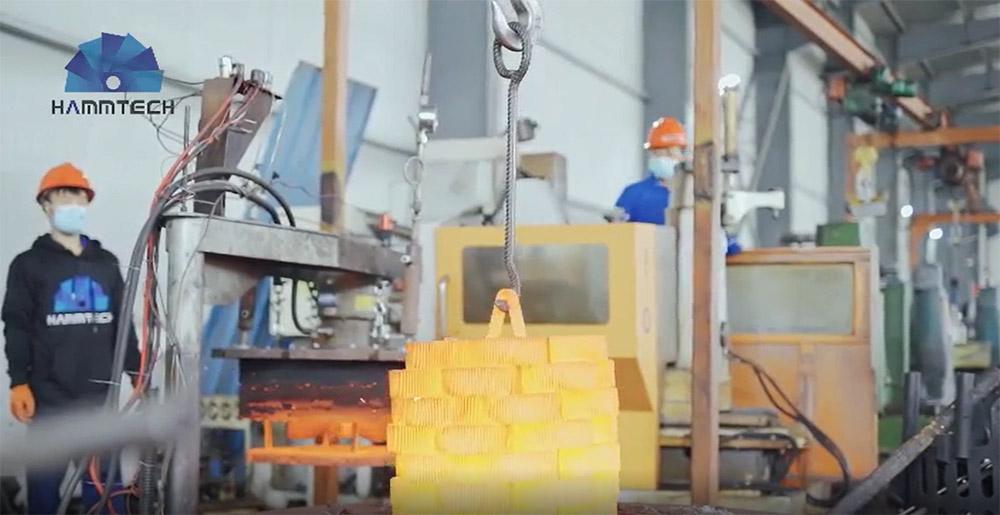

Embonini yokukhiqiza ama-pellet, imishini yokufaka i-ring die noma i-flat die pelleting ivame ukusetshenziselwa ukucindezela izinto eziyimpuphu zibe okuphakelayo kwe-pellet.Kokubili okuyisicaba kanye neringi kuyafa kuncike ekunyakazeni okuhlobene kwerola yokucindezela kanye nedayizi ukuze ibambe into esetshenziswayo iyenze ibe sesimweni sokusebenza esisebenzayo bese iyimpintsha ibe yisimo.Le rola yokucindezela, evame ukubizwa ngokuthi igobolondo le-pressure roller, iyingxenye esemqoka yokusebenza kwesigayo se-pellet, njengokufa kweringi, futhi ingenye yezingxenye ezigqokiwe.

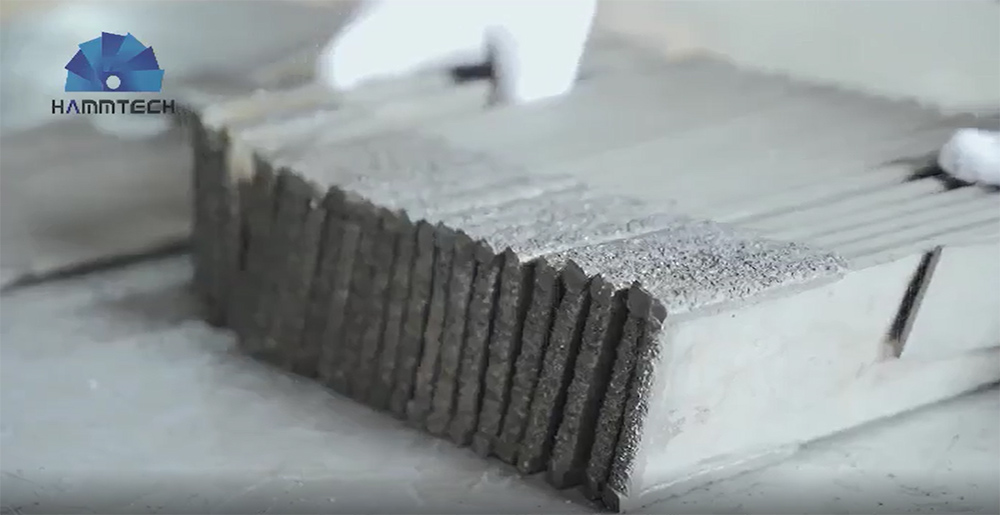

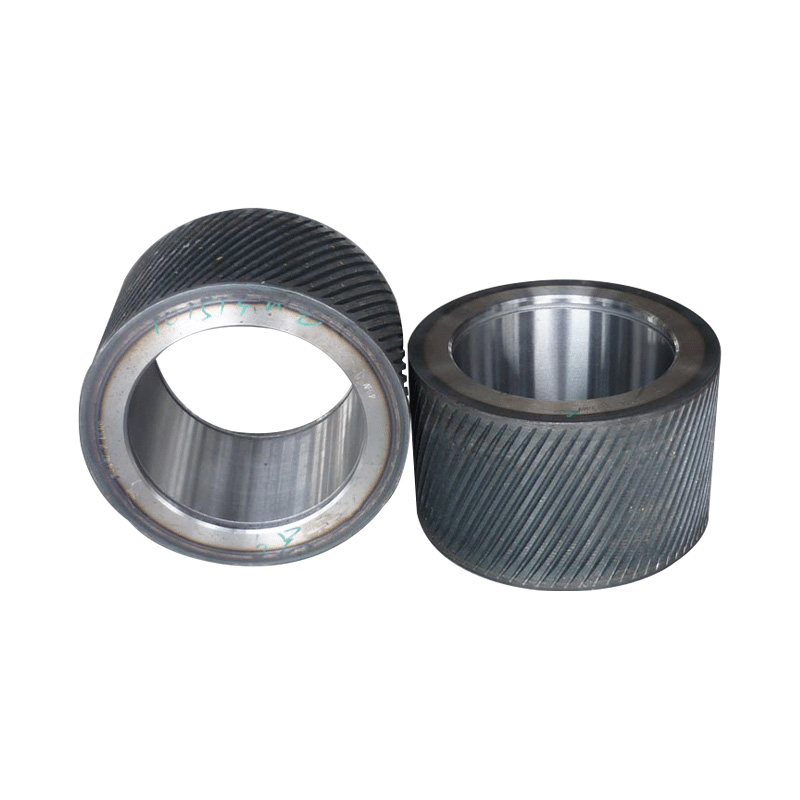

I-rola yokucindezela ye-granulator isetshenziselwa ukuminyanisa okubalulekile kuyindandatho yokufa.Njengoba i-roller ingaphansi kokungqubuzana nokucindezela isikhathi eside, i-circumference yangaphandle ye-roller yenziwa ngomshini ibe yi-grooves, okuthuthukisa ukumelana nokugqoka nokuklebhula futhi kwenza kube lula ukubamba izinto ezikhululekile.

Izimo zokusebenza zama-roller zimbi kakhulu kunezokufa kweringi.Ngaphezu kokugqoka okuvamile kwezinto eziluhlaza kuma-rollers, i-silicate, i-SiO2 esihlabathini, izicucu zensimbi, nezinye izinhlayiya eziqinile ku-raw material ziqinisa ukuguga kuma-rollers.Njengoba isivinini somugqa werola yokucindezela kanye nokufa kwendandatho kuyalingana ngokuyisisekelo, ububanzi berola yokucindezela buphindwe izikhathi ezingu-0.4 kuphela ububanzi bangaphakathi bendandatho yokufa, ngakho izinga lokugqoka le-rola yokucindezela liphakeme izikhathi ezingu-2.5 kunelo ring die.Isibonelo, impilo yethiyori yokuklama ye-pressure roller amahora angu-800, kodwa isikhathi sangempela sokusebenzisa asikho ngaphezu kwamahora angu-600.Kwamanye amafekthri, ngenxa yokusetshenziswa ngendlela engafanele, isikhathi sokusebenzisa singaphansi kwamahora angu-500, futhi ama-roller ahlulekile awasakwazi ukulungiswa ngenxa yokuguga okungathi sína.

Ukugqoka ngokweqile kwama-roller akugcini nje ukunciphisa izinga lokubunjwa kwe-pellet fuel futhi kwandisa izindleko zokukhiqiza, kodwa futhi kuthinta ngokuqondile ukukhiqiza.Ngakho-ke, indlela yokwelula ngokuphumelelayo impilo yesevisi ye-pellet mill rollers iyinkinga enkulu embonini.