Embonini ye-granulation, noma ngabe kuwumshini we-pellet ofuywayo noma umshini wendandatho we-pellet, umgomo wawo wokusebenza ukuncika ekuhambeni okuhlobene phakathi kwengcindezi bese ufaka isiteshi esisebenzayo, bese usika kwizinhlayiya zobude obudingekayo.

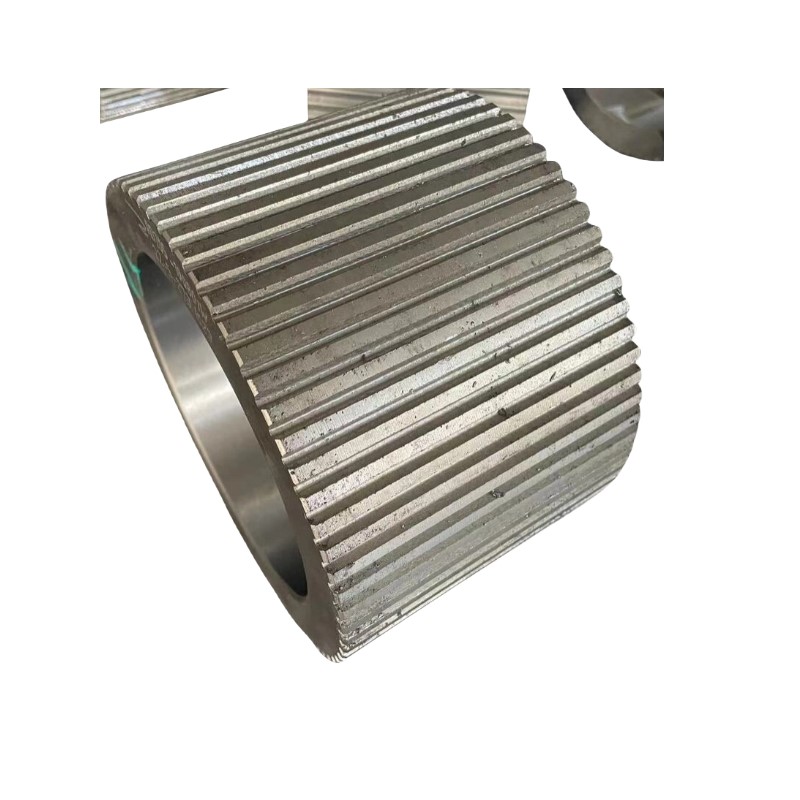

I-Particle Press Roller Shell

I-Pressure Roller Shell ikakhulukazi ifaka shaft e-eccentric, ama-rolling bearnings, i-roller sholl yengcindezi etholwa ngaphandle kwengcindezi yengcindezi yengcindezi, kanye nezinto ezisetshenziselwa ukusekela nokulungisa igobolondo le-roller.

Ingcindezi yengcindezi idonsela impahla emgodini wokubumba bese iyibukisa ngaphansi kwengcindezi emgodini wobumba. Ukuze uvikele i-roller yengcindezi kusuka ekushayeleni futhi wandise amandla okuxinana, kufanele kube nebutho elithile lokungqubuzana phakathi kwengcindezi yengcindezi nokuqukethwe. Ngakho-ke, izinyathelo zokwandisa ukuxabana nokugqokwa kuvame ukuthathwa ngaphezulu kwe-roller roller. Lapho amapharamitha wesakhiwo se-roller yengcindezi kanye nesikhunta anqunywe, ifomu lesakhiwo nosayizi we-areter ebusweni bengcindezi yengcindezi banomthelela omkhulu ekusebenzeni kwenqwaba nasezingeni eliphezulu.

Ukwakheka komhlaba we-Pressure Roller Shell

Kunezinhlobo ezintathu ezijwayelekile ze-Perform Press Rikeler

I-Colleged Groove Type Pressure roller inokusebenza okuhle kokuqalisa futhi isetshenziswa kabanzi kumafektri e-Livestock nasezinkukhu. Kodwa-ke, ngenxa yokudla okuphakelayo ku-groove efakwe ngamazinyo, ukugqokwa kwengcindezi yengcindezi kanye nokubumba kwendandatho akuwona umfaniswano kakhulu, futhi ukugqokwa kwazo zombili iziphetho zengcindezi yengcindezi nokubumba kwendandatho kunzima kakhulu.

I-roller yohlobo lwe-tooned groove ephethe ukucindezelwa ngokubekwa uphawu ilungele ukukhiqizwa kwezinto zokufunda zasemanzini. Izinto ze-Aquatic zithambekele kakhulu ekusheleleni ngesikhathi sokukhishwa. Ngenxa yokubekwa uphawu konqenqemeni ezinhlangothini zombili ze-groove enamazinyo, akulula ukuslayida ezinhlangothini zombili ngesikhathi sokuphakelwa kokuphakelayo, okuholela ekusatshalalisweni okufanayo kokuphakelayo. Ukugqokwa kwengcindezi yengcindezi kanye nokubumba kwendandatho nakho kufana kakhulu, okuholela ngobude obungaguquki be-pellets ekhiqizwayo.

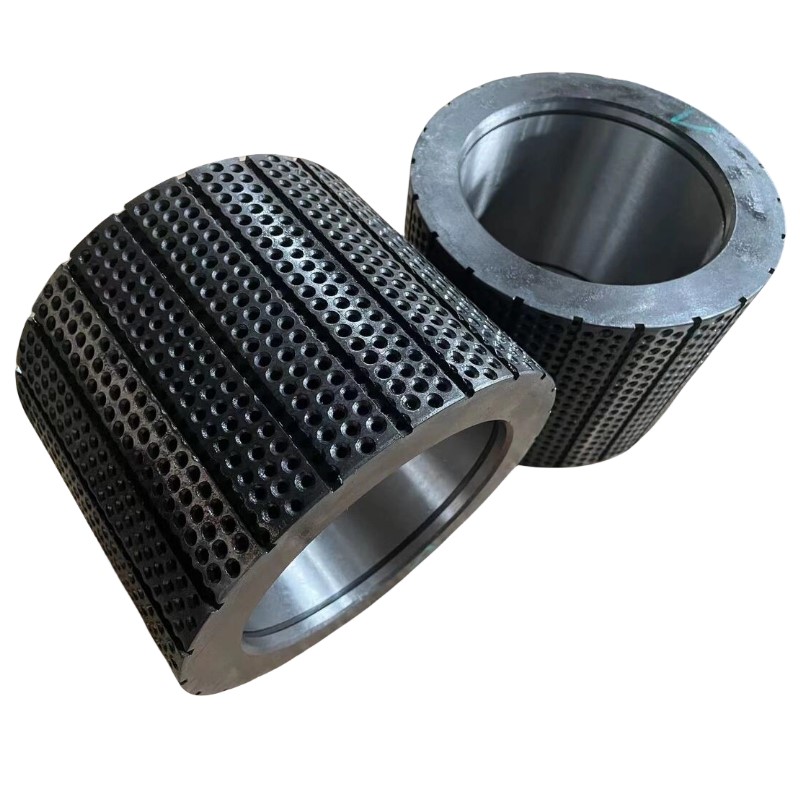

Inzuzo ye-honeycomb roller ukuthi ukugqokwa kwesikhunta sendandatho kuyafana, futhi ubude bezinhlayiya ezikhiqizwayo futhi buvumelana. Kodwa-ke, ukusebenza kwekhoyili kumpofu, okuthinta umphumela we-granulator futhi akuvamile njengokusetshenziswa kohlobo lwe-slot ekukhiqizweni kwangempela.

Lokhu okulandelayo kufingqiwe kwezinhlobo eziyi-10 zemishini yokucindezela umshini we-polling for Baashell Pressure Ring Ring Solds, futhi izinto ezi-3 zokugcina nakanjani nalezo ongazange uzibone!

No.10 groove hlobo

Cha.9 Uhlobo Lokuvalwa Kwe-Groove

No.8 Uhlobo lwezinyosi

No.7 Diamond Demond

Cha.6 I-Groove Ethambekele

No.5 groove + honeycomb

Cha.4 I-Groove + Yezinyosi Evaliwe

Cha.3 I-Groove + yezinyosi

Cha. I-ripple yezinhlanzi yamathambo

NO.1 enziwe nge-arc-shaped ripple

Imodeli yeSeppecial: UTungsten Carbide Coller Shell

Indlela yokwelashwa yokushona kwengcindezi yengcindezi yomshini wezinhlayiyana

Ngenxa yemvelo enzima yokusebenza, ukuqina okuphezulu, kanye nezinga lokugqoka elisheshayo le-Fress Roller Shell, umfutho wengcindezi yingxenye esengozini yomshini wezinhlayiyana futhi udinga ukushintshwa njalo. Ukusebenza okukhiqizwayo kukhombisile ukuthi inqobo nje uma izici zezinto zokukhiqiza zishintsha noma ezinye izimo zishintsha ngesikhathi sokucutshungulwa, into yokushona kwengcindezi yengcindezi yomshini wezinhlayiyana kungenzeka. Uma kukhona ukwehla kwengcindezi yengcindezi ngesikhathi senqubo ye-granution, sicela ungesabi. Ngemininingwane ethile, sicela ubheke amasu alandelayo:

Isizathu 1: Ukuqina Okungesihle Kokucindezela Kwengcindezi kanye nokufakwa kwe-spindle

Isixazululo:

Bheka ukuthi ukufakwa kwengcindezi yengcindezi ye-roller kunengqondo ukugwema ukwenza i-rollell shell yengcindezi ukuze iphambuke ohlangothini olulodwa.

Isizathu 2: Umlomo weBell of the Calling Mold ungaphansi komhlaba, okwenza isikhunta singadli izinto zokwakha

Isixazululo:

Bheka ukugqokwa kwama-clamps, amasondo okuhambisa, kanye namasongo e-granulator.

Lungisa ukuguqulwa kwendandatho yokubumba izindandatho, ngephutha elingeqi ku-0.3mm.

Igebe eliphakathi kwezingcindezi zengcindezi kufanele lishintshwe: uhhafu wendawo yokusebenza yabasebenza kwengcindezi isebenza nesikhunta, futhi isondo lokulungiswa kwegebe futhi isikulufa sokukhiya kufanele futhi siqiniseke ukuthi sisesimweni esihle sokusebenza.

Lapho i-roller yengcindezi ishelela, ungavumeli umshini wezinhlayiyana wezinhlayiyana ungazenzi isikhathi eside bese ulindela ukuba ikhiphe impahla ngokwayo.

Isilinganiso sokucindezela kwesigaxa sokubumba izindandatho esisetshenzisiwe siphezulu kakhulu, okubangela ukumelana okuphezulu kwezinto ezibonakalayo ngesikhunta futhi futhi kungenye yezizathu zokushelela kwe-roller roller.

Umshini wePellet akufanele uvunyelwe ukungasebenzi ngokungadingekile ngaphandle kokudla okubonakalayo.

Isizathu 3: Ukubhekelwa kwengcindezi kwengcindezi kuyabambeka

Isixazululo:

Buyisela amabhere we-roller wengcindezi.

Isizathu 4: I-Pressure Roller Shell ayizungezwanga

Isixazululo:

Izinga le-roller Shell alinakufanelekanga, lishintshe noma lilungise i-roller Shell.

Lapho i-roller yengcindezi ishelela, kufanele imiswe ngesikhathi esifanele ukugwema ukungqubuzana okungazeleleki kwengcindezi.

Isizathu 5: Ukugoba noma ukukhulula kwengcindezi ye-roller spindle

Isixazululo:

Faka esikhundleni noma uqinise i-spindle, bese uhlola isimo sengcindezi ye-roller spindle lapho ungene esikhundleni sokubumba kwendandatho nengcindezelo yengcindezi.

Isizathu 6: Indawo esebenzayo ye-Roller yengcindezi ifakwe ngaphakathi kobuso obusebenzayo bokubumba kwendandatho (ukuwela onqenqemeni)

Isixazululo:

Bheka ukuthi i-roller yengcindezi ifakwe ngokungafanele futhi isuse esikhundleni sayo.

Bheka ukuthi i-eccentric shaft ye-roller yengcindezi ikhubazekile.

Bheka ukugqoka emibhalweni esemqoka yemishayo noma ama-bushings womshini wezinhlayiyana.

Isizathu 7: Ukuvunyelwa kwe-spindle of the granulator kukhulu kakhulu

Isixazululo:

Hlola imvume yokuqinisa i-granulator.

Isizathu 8: Izinga lokubhoboza lesikhunta sendandatho liphansi (ngaphansi kwama-98%)

Isixazululo:

Sebenzisa i-pistol drill ukuwela umgodi wokubumba, noma ukubilisa emafutheni, ugaye ngaphambi kokudla.

Isizathu 9: Izinto zokusetshenziswa eziluhlaza zinama-coarse kakhulu futhi zinokuqukethwe umswakama okuphezulu

Isixazululo:

Nakisisa ukugcina okuqukethwe umswakama ongama-15%. Uma okuqukethwe umswakama wezinto zokwakha ezivuthiwe ziphezulu kakhulu, kuzoba nokuvinjwa kokubumba kanye nokushefa ngemuva kokusetshenziswa okuluhlaza faka isikhunta sendandatho. Uhla lokulawula umswakama lwezinto eziluhlaza luphakathi kuka-13-20%.

Isizathu 10: Ukuphakelwa okusha okubusayo ngokushesha okukhulu

Isixazululo:

Lungisa ijubane ukuze uqinisekise ukuthi i-roller yengcindezi inokuthambekela okwanele, ukuvikela i-roller yengcindezi kusuka ekushayeleni, futhi ngokushesha hlola ukugqokwa kwesikhunta sendandatho nengcindezi.

Isikhathi sePosi: Mar-25-2024