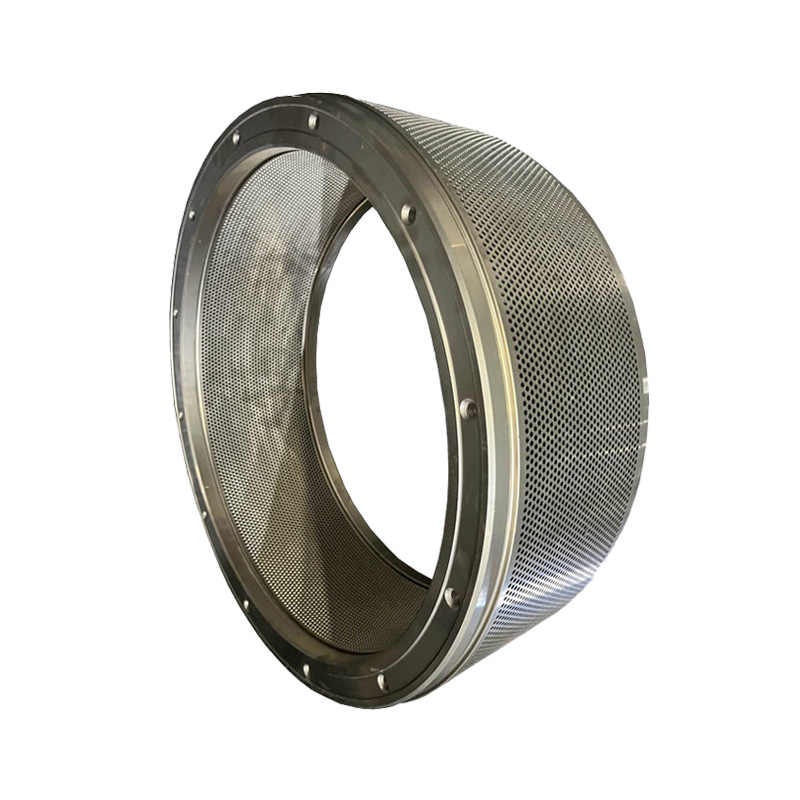

Igobolondo le-Stainless Steel Roller elineziphetho ezivulekile

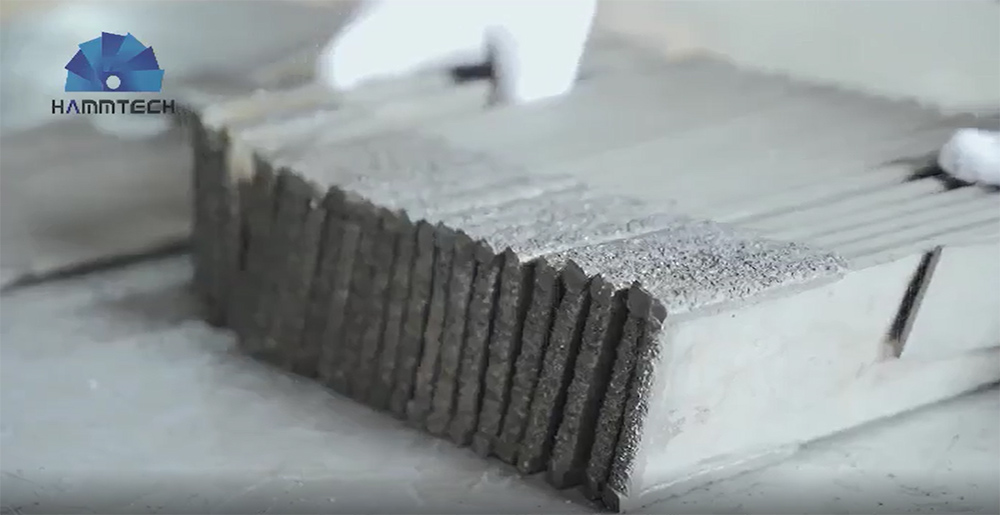

● Igobolondo ngalinye le-pellet mill roll lakhiwa ngokunemba okwedlulele kusetshenziswa insimbi engagqwali yekhwalithi ephezulu kakhulu.

● Amagobolondo ethu amelana kakhulu nokuguga, ukuphuka, nokugqwala.

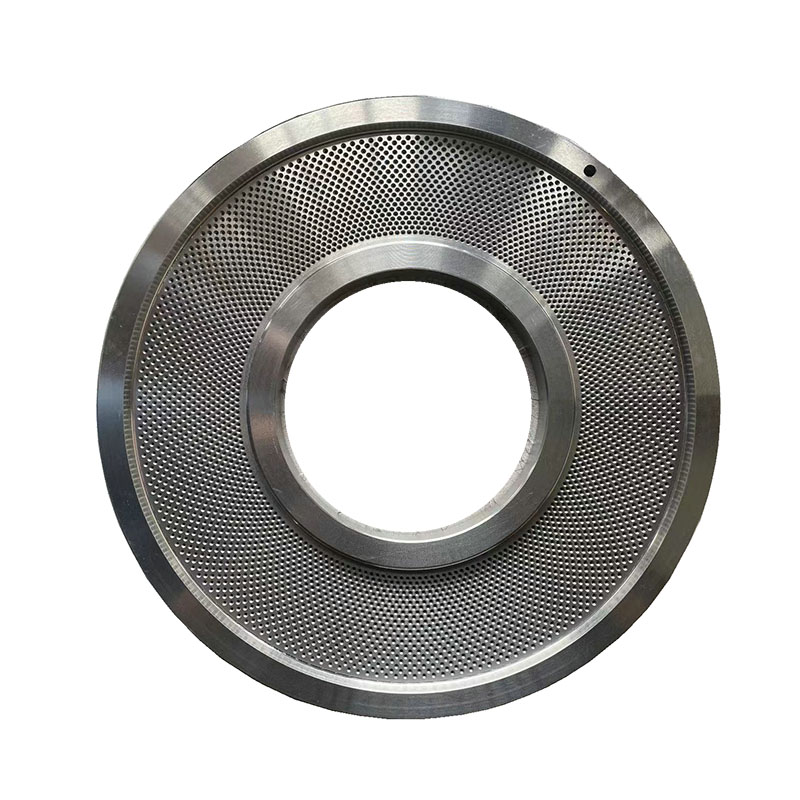

| Umkhiqizo | Igobolondo le-roller |

| Okubalulekile | Insimbi engagqwali |

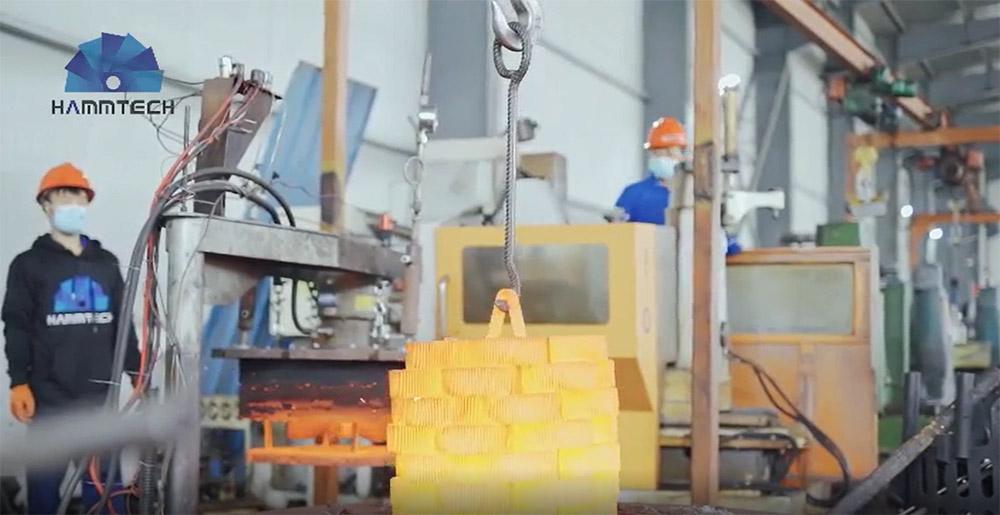

| Inqubo | I-Lathing, i-milling, i-drilling |

| Usayizi | Njengomdwebo nezidingo zamakhasimende |

| Ukuqina Kobuso | 58-60HRC |

| Umbiko Wokuhlolwa Kwemishini | Kuhlinzekiwe |

| Iphakheji | Ngokwezicelo zamakhasimende |

| Umbiko Wokuhlolwa Kwemishini | Kuhlinzekiwe |

| Izici | 1. Iqinile, ihlala isikhathi eside 2. Imelana nokugqwala 3. I-coefficient ephansi yokungqubuzana 4. Izidingo zokulungisa eziphansi |

Igobolondo le-roller lisebenza ngaphansi kwezimo ezinzima kakhulu. Amandla amakhulu adluliselwa kusuka endaweni efayo ngokusebenzisa ama-bearings kuya ku-shaft yokusekela i-roller. I-friction idala imifantu yokukhathala ukuthi ivele phezulu. Ngemuva kokujula okuthile kokuqhekeka kokukhathala kwenzeke ngesikhathi sokukhiqiza, impilo yesevisi yegobolondo inwetshwa ngokufanele.

Ubude besikhathi sokuphila kwegobolondo le-roller bubalulekile, njengoba ukushintshwa njalo kwegobolondo le-roller kungalimaza nokufa kweringi. Ngakho-ke, lapho uthenga imishini ye-pelletizing, izinto zegobolondo le-roll nazo kufanele zicatshangelwe. I-Chrome steel alloy material iyathandeka ngoba inokumelana nokukhathala okuhle futhi ifanele izidingo zokusebenza ezindaweni ezinokhahlo.

Igobolondo elihle le-roller alenziwa nje ngezinto ezinhle kuphela kodwa futhi lihambisana nezici ezinhle kakhulu zokufa kwalo. Umhlangano ngamunye we-die and roller uhlala ndawonye njengeyunithi, inweba impilo ye-die and roller futhi ikwenze kube lula ukuyigcina nokuyiguqula.

Singahlinzeka ngamasethi aphelele ezinsiza zokugaya i-pellet, njengama-pulverizer hammer blades, i-granulator ring, i-flat dies, ama-discs okugaya i-granulator, amagobolondo e-granulator roller, amagiya (amancane / amancane), ama-bearings, ama-shafts angenalutho, amaphini okuphepha, ama-couplings, ama-giya shaft, ama-roller amagobolondo ahlukahlukene.