Impilo yesevisi ye-isando bladeihlobene nempahla ye-hammer blade ngokwayo, uhlobo lwezinto ezichotshoziwe, njll. Impahla ye-hammer blade iyisici esibaluleke kakhulu esithinta ukuphila kwayo. Ama-hammer blades emakethe ahlukaniswe cishe izigaba ezintathu: izindwani zesando ezijwayelekile, izindwani zesando ezishiselwe i-tungsten carbide, kanye nezindwani zesando ezishiselwe i-tungsten carbide.

Phakathi kwazo, inqobo nje uma ucezu lwesando olujwayelekile luwucezu lwesando oluphethwe ukushisa, noma kusetshenziswa ucezu lwesando sensimbi engu-65Mn, intengo yalolu hlobo lwesicucu sesando ishibhile, kodwa impilo yesevisi ehambisanayo nayo imfushane.

Izando zokushisela isifutho se-Tungsten carbide zisetshenziswa kakhulu emakethe, kusetshenziswa ubuchwepheshe bokushisela i-oxyacetylene ukufafaza i-weld tungsten carbide powder phezu kwesando substrate, bese kushisa ukuphatha isando ukukhiqiza umkhiqizo wokugcina. Kodwa-ke, ngenxa yemvelo yokukhiqiza enokhahlo kanye nomthelela wekhwalithi ye-tungsten carbide welding wire, ikhwalithi yesando sokugcina se-tungsten carbide nayo ayilingani, ngokuvamile ihambisana namaphutha afana nama-pores kanye nokufakwa kungqimba lwe-weld, okuthinta kakhulu impilo yayo yesevisi. Ikakhulukazi uma izinto eziqinile kancane ziphukile, kulula ukubangela ungqimba lwe-weld ukuba lugoqe. Ngaphezu kwalokho, inqubo yokukhiqiza ihambisana nenani elikhulu lothuli namagesi ayingozi, angakwazi ukufeza ukuzenzekelayo, futhi amathemba awathembisi kakhulu.

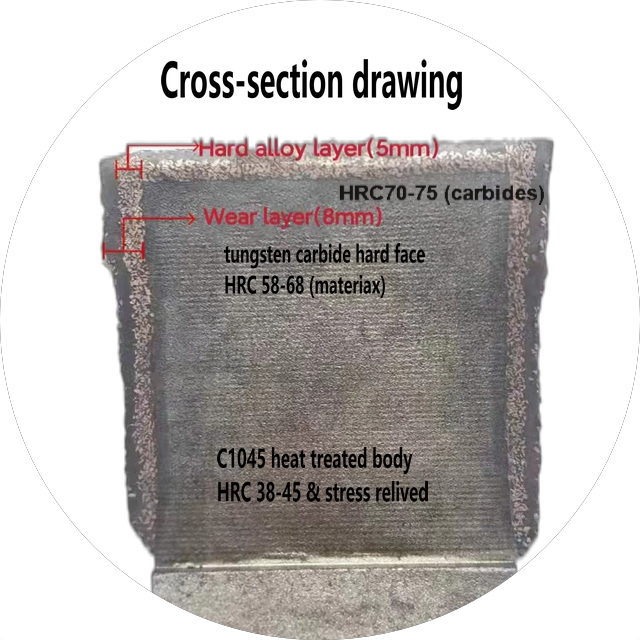

Izando zokushisela ze-tungsten carbide fusion ye-HMT zisebenzisa ubuchwepheshe bokuvala i-plasma welding, obubeka ungqimba lwezinhlayiya zengxubevange eqinile esando esingaphansi, esifinyelela cishe ukujiya okufanayo phakathi kwesando esingaphansi kanye nongqimba oluqinile lwengxubevange yokushisela. Ngesikhathi esifanayo, inhlayiya ngayinye eqinile ye-alloy ine-multi-directional cutting edge, ithuthukisa kakhulu ukusebenza kwe-shear kwesando. Izingcezu zesando eziqinile ze-HMT ezihlanganisiwe zisebenza kahle kakhulu, zinokungagugi okuphakeme, impilo yesevisi, ukumelana nomthelela, nokusebenza kahle kokuchotshozwa uma kuqhathaniswa nezingcezu zesando ezishiselwe i-tungsten carbide. Ngaphezu kwalokho, inqubo yokukhiqiza ingenziwa ngokuzenzakalelayo futhi ivumelane nemvelo, ikwenze kube umkhuba wokukhiqiza ucezu lwesando lwesimanje.

Ukuchotshozwa kwezinto zokwakha nakho kunomthelela omkhulu empilweni yesevisi yezando, futhi ukusebenzisa izando ezihlukene ukuchoboza izinto ezihlukene kungathuthukisa kakhulu ukusebenza kahle kokuchotshozwa. Ezinye izinto zinokuqina okuphezulu, ngakho-ke amandla okuthinta isando nawo anamandla kakhulu. Isibonelo, lapho isifunzo se-bamboo nesando sokushisela isifutho se-tungsten carbide siphuka, ungqimba lwe-weld luvame ukuwa. Okwezinto ezisetshenziswayo ezinokugqoka okubalulekile, ubude bongqimba obungagugi kufanele bunyuswe ngo-100mm, njengokuphakelayo kwamakhoba okusanhlamvu. Kukhona nesigaba samabhulokhi okhuni achotshoziwe, anamandla amakhulu kanye nokuguga, futhi izando zokushisela isifutho se-tungsten carbide azikwazi ukusetshenziswa nhlobo. Ngezando ezijwayelekile, impilo yabo yesevisi ifushane. Ngokuchotshozwa kwezinto ezinjalo, izando zokushisela ze-HMT's hard alloy fusion zingahlangabezana nezidingo kahle kakhulu. Ngemva kokusetshenziswa okungokoqobo komkhiqizi wamabhulokhi ezinkuni ezichotshoziwe, kufakazelwe ukuthi izando zokushisela ze-HMT eziqinile zengxubevange zingahlangabezana nezimfuneko kahle kakhulu. Ngaphezu kwalokho, umswakama wommbila nawo unomthelela omkhulu ekusebenzeni kahle kokuchotshozwa. Uma umswakama uphezulu, ukugqokwa kwesando kuba kukhulu futhi impilo yesevisi iba mfushane.

Isikhathi sokuthumela: Apr-02-2025