Umshini we-pellet iyithuluzi lokucindezela i-biomass pellet fuel kanye ne-pellet feed, phakathi kwayo i-roller yokucindezela iyingxenye yayo eyinhloko nengxenye esengozini. Ngenxa yomthwalo wayo osindayo kanye nezimo zokusebenza ezinzima, ngisho nekhwalithi ephezulu, ukuguga akunakugwenywa. Enkambweni yokukhiqiza, ukusetshenziswa kwama-roller okucindezela kuphezulu, ngakho-ke izinto ezibonakalayo kanye nenqubo yokukhiqiza yama-rollers okucindezela kubaluleke kakhulu.

Ukuhlaziywa kokwehluleka kwe-roller yokucindezela yomshini wezinhlayiyana

Inqubo yokukhiqiza ye-rola yokucindezela ihlanganisa: ukusika, ukubumba, ukujwayelekile (i-annealing), umshini onzima, ukucisha kanye nokushisa, umshini wokwenza izinto ngokunemba, ukucisha indawo, kanye nomshini wokunemba. Ithimba lochwepheshe lenze ucwaningo lokuhlola mayelana nokuguga kwamafutha e-biomass pellet ukuze akhiqize futhi acutshungulwe, okuhlinzeka ngesisekelo sethiyori sokukhethwa okunengqondo kwezinto ze-roller nezinqubo zokwelashwa kokushisa. Okulandelayo yiziphetho nezincomo zocwaningo:

Amazinyo kanye nokuklwebheka kuvela ebusweni berola yokucindezela ye-granulator. Ngenxa yokuguga kokungcola okuqinile okufana nesihlabathi namafayili okusansimbi ku-rola yokucindezela, kungokokugqoka okungavamile. Isilinganiso sokugqokwa kwangaphezulu singama-3mm, kanti ukugqokwa kwezinhlangothi zombili kuhlukile. Uhlangothi lokuphakelayo lunokuguga okunzima, nokuguga okungu-4.2mm. Ikakhulukazi ngenxa yokuthi ngemuva kokuphakelwa, i-homogenizer yayingenaso isikhathi sokusabalalisa izinto ngokulinganayo futhi yafaka inqubo yokukhipha.

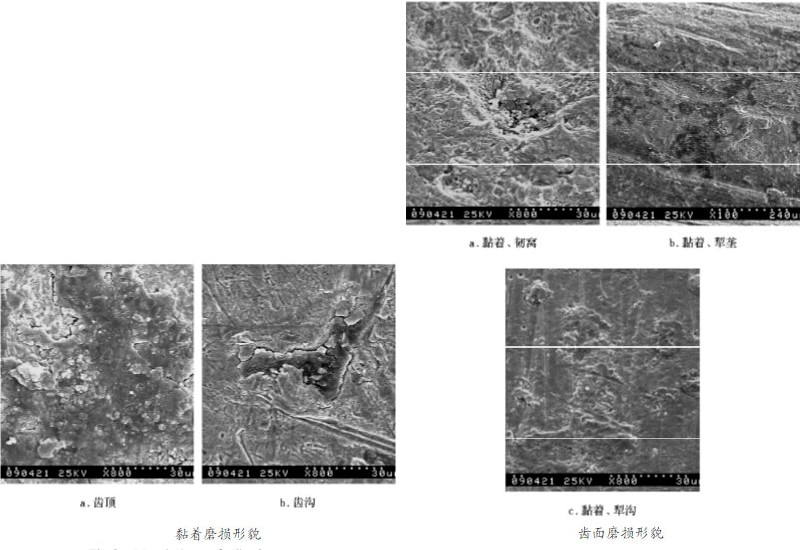

Ukuhlaziywa kokwehluleka kokugqoka kwe-Microscopic kubonisa ukuthi ngenxa yokugqoka kwe-axial ebusweni be-roller yokucindezela okubangelwa izinto zokusetshenziswa, ukuntuleka kwezinto ezibonakalayo ku-roller yokucindezela kuyimbangela eyinhloko yokwehluleka. Izinhlobo eziyinhloko zokugqoka ziyi-adhesive wear kanye ne-abrasive wear, ene-morphology efana nemigodi eqinile, imigodi yokulima, ama-grooves okulima, njll., okubonisa ukuthi ama-silicates, izinhlayiya zesihlabathi, amafayili ensimbi, njll. ezintweni ezingavuthiwe zinokuguga okukhulu ebusweni be-roller yokucindezela. Ngenxa yesenzo somhwamuko wamanzi nezinye izici, udaka olufana namaphethini luvela ebusweni be-roller yokucindezela, okuholela ekuqhekekeni kokugqwala kwengcindezi ebusweni be-roller yokucindezela.

Kunconywa ukuthi wengeze inqubo yokususa ukungcola ngaphambi kokuchoboza izinto zokusetshenziswa ukuze kukhishwe izinhlayiya zesihlabathi, amafayili ensimbi, nokunye ukungcola okuxutshwe ezintweni ezingavuthiwe, ukuze kuvinjelwe ukuguga okungavamile nokuklebhuka kuma-roller okucindezelayo. Shintsha ukuma noma indawo yokufaka ye-scraper ukuze usabalalise ngokulinganayo impahla ekamelweni lokucindezela, ukuvimbela amandla angalingani ku-roller yokucindezela futhi ukhulise ukuguga ebusweni be-roller yokucindezela. Ngenxa yokuthi i-roller yokucindezela ngokuyinhloko ihluleka ngenxa yokugqoka okuphezulu, ukuze kuthuthukiswe ubulukhuni bayo obuphezulu, ukumelana nokugqoka, nokumelana nokugqwala, izinto ezivimbela ukugqokwa kanye nezinqubo ezifanele zokwelashwa kokushisa kufanele kukhethwe.

Ukwelashwa kwezinto kanye nenqubo ye-pressure rollers

Ukwakheka kwezinto ezibonakalayo kanye nenqubo ye-roller yokucindezela kuyizimfuneko zokunquma ukumelana nokugqoka kwayo. Izinto ezisetshenziswa kakhulu zamarola zifaka i-C50, i-20CrMnTi, ne-GCr15. Inqubo yokukhiqiza isebenzisa amathuluzi omshini we-CNC, futhi i-roller surface ingenziwa ngokwezifiso ngamazinyo aqondile, amazinyo e-oblique, izinhlobo zokubhoboza, njll ngokuvumelana nezidingo. I-Carburization quenching noma ukwelashwa kokushisa kwe-high-frequency quenching kusetshenziselwa ukunciphisa ukuwohloka kwe-roller. Ngemuva kokwelashwa kokushisa, ukunemba kwemishini kwenziwa futhi ukuze kuqinisekiswe ukugxila kwemibuthano yangaphakathi nangaphandle, engandisa impilo yesevisi ye-roller.

Ukubaluleka kokwelashwa kokushisa kwamarola okucindezela

Ukusebenza kwe-roller yokucindezela kufanele kuhlangabezane nezidingo zamandla aphezulu, ukuqina okuphezulu (ukumelana nokugqoka), kanye nokuqina okuphezulu, kanye nokuhleleka okuhle (kuhlanganise nokupholisha okuhle) nokumelana nokugqwala. Ukwelashwa kokushisa kwama-rollers okucindezela kuyinqubo ebalulekile ehloswe ukukhulula amandla ezinto ezibonakalayo nokuthuthukisa ukusebenza kwabo. Kunomthelela oqondile ekunembeni kokukhiqiza, amandla, impilo yesevisi, kanye nezindleko zokukhiqiza.

Okokusebenza okufanayo, izinto eziye zabhekana nokwelashwa kokushisisa ngokweqile zinamandla aphakeme kakhulu, ubulukhuni, nokuqina uma kuqhathaniswa nezinto ezingazange zelashwe ngokwedlulele. Uma kungacinywa, impilo yesevisi ye-roller yokucindezela izoba mfushane kakhulu.

Uma ufuna ukuhlukanisa phakathi kwezingxenye eziphethwe ukushisa nezingaphathwanga ukushisa eziye zasebenza ngokunemba, akunakwenzeka ukuzihlukanisa kuphela ngobulukhuni nombala we-oxidation wokwelapha ukushisa. Uma ungafuni ukusika nokuhlola, ungazama ukuhlukanisa ngokuthepha umsindo. Isakhiwo se-metallographic kanye nokungqubuzana kwangaphakathi kwama-castings nama-workpieces acishiwe futhi athambile ahlukile, futhi angahlukaniswa ngokuthepha kancane.

Ukuqina kokwelashwa kokushisa kunqunywa izici eziningana, okuhlanganisa ibanga lezinto ezibonakalayo, ubukhulu, isisindo se-workpiece, ukwakheka kanye nesakhiwo, kanye nezindlela zokucubungula ezilandelayo. Isibonelo, uma usebenzisa i-spring wire ukwenza izingxenye ezinkulu, ngenxa yobukhulu bangempela be-workpiece, imanuwali ithi ubulukhuni bokwelashwa kokushisa bungafinyelela ku-58-60HRC, okungenakufinyelelwa ngokuhambisana nezinsimbi zokusebenza zangempela. Ngaphezu kwalokho, izinkomba zobulukhuni obungenangqondo, njengokuqina okuphezulu ngokweqile, zingaholela ekulahlekelweni kokuqina kwe-workpiece futhi kubangele ukuqhekeka ngesikhathi sokusetshenziswa.

Ukwelashwa kokushisa akufanele kuqinisekise kuphela inani elifanele lobulukhuni, kodwa futhi linake ekukhethweni kwayo kwenqubo kanye nokulawulwa kwenqubo. Ukucima nokushisa ngokweqile kungafinyelela ubulukhuni obudingekayo; Ngokufanayo, ngaphansi kokushisisa ngesikhathi sokucisha, ukulungisa izinga lokushisa lokushisa nakho kungahlangabezana nebanga lobunzima obudingekayo.

I-Baoke pressure roller yenziwe ngensimbi yekhwalithi ephezulu i-C50, iqinisekisa ukuqina nokumelana nokugqokwa kwerola yomshini wezinhlayiyana ezivela emthonjeni. Ihlanganiswe nobuchwepheshe obuhle bokwelapha ukushisa okucisha izinga lokushisa eliphezulu, inweba kakhulu impilo yayo yesevisi.

Isikhathi sokuthumela: Jun-17-2024