Uma kuqhathaniswa nensimbi yomdabu ye-manganese noma insimbi yamathuluzi, izando ze-tungsten carbide zinezinzuzo eziphawulekayo ekumelaneni nokugqokwa nempilo yesevisi. Nakuba insimbi ye-manganese noma insimbi yamathuluzi nayo inokungagugi okuthile, i-tungsten carbide hammer mill blade inokuqina okuphezulu nokumelana nokuguga okuqinile, ikakhulukazi uma isebenza ngezinto eziqinile.

I-Tungsten carbide hammer knife crusher isetshenziswa kabanzi ukuchotshozwa okumahhadla nokuphakathi kwezinto ezahlukahlukene ezinamandla acindezelayo angaphansi kwama-megapascal angama-320. Inesilinganiso esikhulu sokuchotshozwa, ukusebenza okulula, ukuguquguquka ezinhlotsheni ezihlukahlukene zezinto zokwakha, namandla okuchoboza aqinile, futhi ithatha ingxenye enkulu emkhakheni wemishini yokuchoboza. I-Hammer knife crusher ilungele ukuchoboza izinto ezihlukahlukene eziphukayo namaminerali, futhi isisetshenziswe kabanzi ezimbonini ezihlukahlukene ezifana ne-electronics, imithi, i-ceramics, i-polycrystalline silicon, i-aerospace, ingilazi ebonakalayo, amabhethri, amabhethri amathathu e-fluorescent powder, amandla amasha, i-metallurgy, amalahle, i-ore, imboni yamakhemikhali, izinto zokwakha, i-geology ye-dischage kanye ne-dischage yomsebenzisi, njll. usayizi wezinhlayiyana ukuhlangabezana nezidingo ezahlukene zabasebenzisi abahlukene be-crusher. Ama-crusher ummese wesando ikakhulukazi ancike emthelela wokuchoboza izinto. Inqubo yokuchoboza icishe ibe kanje: impahla ingena ku-crusher futhi ichotshozwe umthelela wekhanda lesando elijikelezayo ngesivinini esikhulu. Impahla echotshoziwe ithola amandla e-kinetic ekhanda lesando bese igijima ibheke kubha yesisefo ngaphakathi kohlaka ngesivinini esikhulu. Ngesikhathi esifanayo, izinto zokwakha zishayisana futhi zichotshozwa izikhathi eziningi. Izinto ezincane kunegebe eliphakathi kwemigoqo yesisefo zikhishwa esikhaleni, futhi ezinye izinto ezinkulu zichotshozwa futhi ngomthelela, ukugaya, nokukhama kwekhanda lesando kubha yesisefo. Izinto ezibonakalayo zikhishwa esikhaleni ngekhanda lesando, ngaleyo ndlela kutholwe umkhiqizo wosayizi wezinhlayiyana oyifunayo.

Izici zomkhiqizo:

1. Ukuguga okuphansi kakhulu (PPM) kungavimbela ukungcoliswa kwezinto.

2. Impilo ende yesevisi kanye nezindleko zokusebenza eziphansi zizonke.

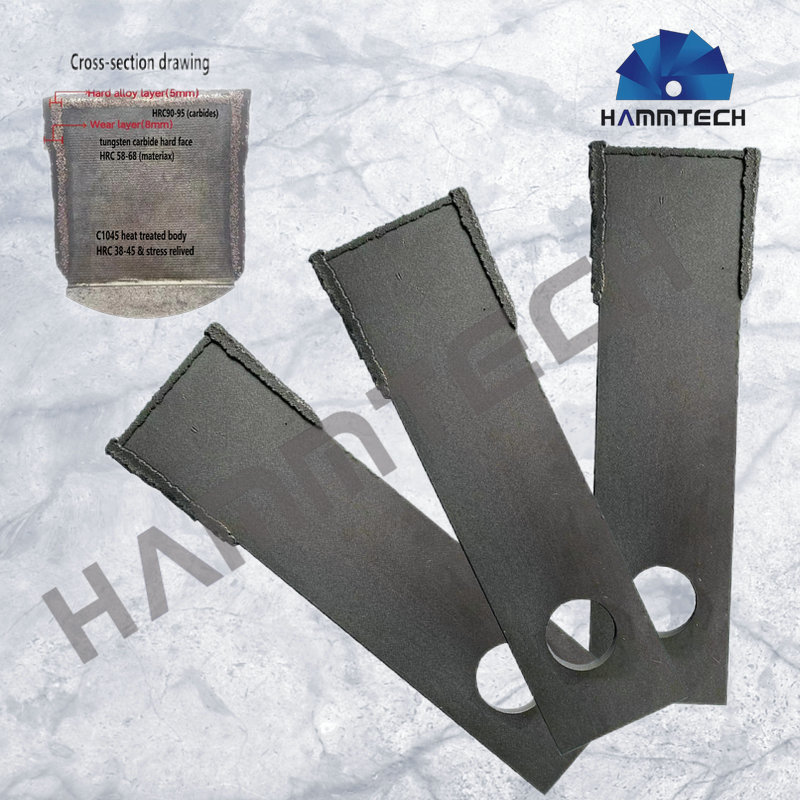

3. Ikhanda lesando lenziwe ngezinto ze-tungsten carbide, ezikwazi ukumelana nokuguga, ukumelana nokugqwala, ukumelana nokushayisana, kanye nokumelana nezinga lokushisa eliphezulu.

4. Uma usebenza, uthuli luncane, umsindo uphansi, nokusebenza kahle.

Izando ze-Tungsten carbide zifanelekile ukuchoboza izinto ezihlukahlukene, kuhlanganise nezinto eziqinile ezifana nommbila, ukudla kwe-soya, amabele, njll. Ngaphezu kwalokho, izingcezu zesando ze-tungsten carbide nazo zinokuphikiswa kwe-asidi, ukumelana ne-alkali, ukumelana nokushisa okuphansi, ukumelana nomlilo nezinye izakhiwo, ezifanele izindawo zokusebenza ezinokhahlo ezihlukahlukene.

Izimpawu Nezimo Zokusebenza ze-Tungsten Carbide Hammer beater

Ukuqina okuphezulu: I-Tungsten carbide hammer beater inokuqina okuphezulu kakhulu futhi ingasika futhi igxobe cishe noma iyiphi enye into.

Ukumelana nokugqoka: Ngenxa yokuqina kwayo okuphezulu, i-tungsten carbide hammer mill beater igqoka kancane kakhulu ngesikhathi sokuchotshozwa futhi ifanele ukusetshenziswa isikhathi eside.

Ukumelana nokushisa okuphezulu: I-Tungsten carbide hammer beater inokumelana nezinga lokushisa eliphakeme kakhulu futhi ingagcina ukusebenza kwayo ngesikhathi sokusebenza ngesivinini esikhulu.

Ukusebenza okubanzi: Ifanele izindawo zokusebenza ezahlukahlukene ezinokhahlo, njengokumelana ne-asidi, ukumelana ne-alkali, ukumelana nezinga lokushisa eliphansi, ukumelana nomlilo, njll.

Ukuhluka kwezando zethu ze-tungsten carbide;

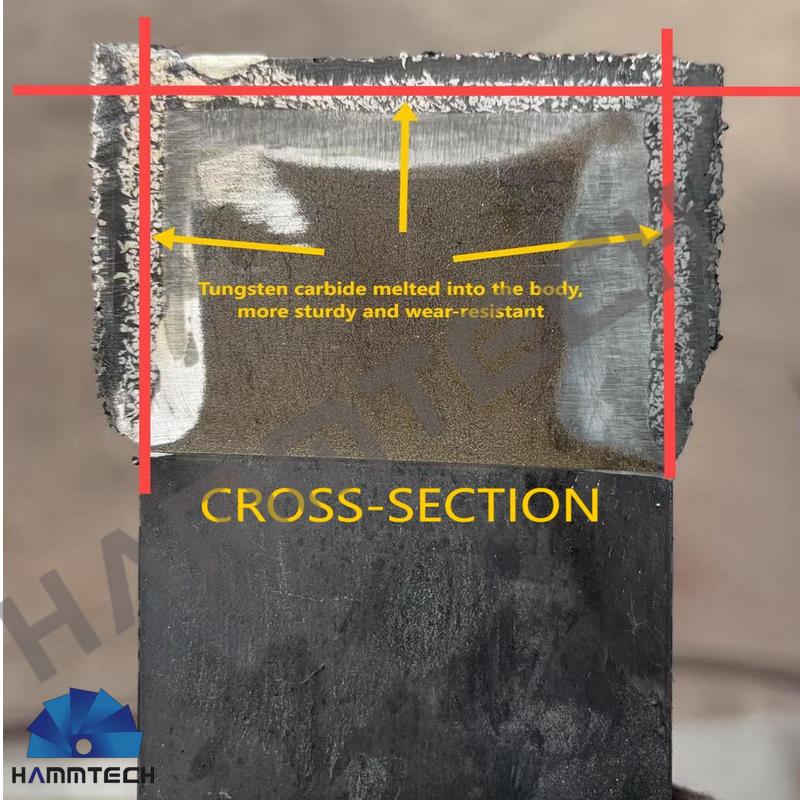

Samukela ubuchwepheshe bokushisela izinhlayiyana ze-hard alloy, okwakha ichibi lokuncibilika kwensimbi lokushisa okuphezulu endaweni yokusebenza, futhi ngokufanayo ithumela izinhlayiya ze-alloy eqinile echibini lokuncibilika. Ngemuva kokupholisa, izinhlayiya ze-alloy eziqinile zakha ungqimba oluqinile lwe-alloy. Ngenxa yokuncibilika nokuqina komzimba wensimbi, kwakheka ungqimba olungagugi, futhi azikho izinkinga ezifana nokuqhekeka kwe-welding noma ukuxebuka.

Isikhathi sokuthumela: Dec-20-2024