1. I-crusher izwa ukundindizela okunamandla nokungavamile

Isizathu: Isizathu esivame kakhulu sokudlidliza kungenxa yokungalingani kwe-turntable, okungabangelwa ukufakwa okungalungile nokuhlelwa kwezintambo zesando; Ama-sando blades agqoke kakhulu futhi awazange ashintshwe ngesikhathi; Ezinye izingcezu zesando zibanjiwe futhi azikhululwa; Ukulimala kwezinye izingxenye ze-rotor kuholela ekungalingani kwesisindo. Ezinye izinkinga ezidala ukudlidliza zihlanganisa: ukuwohloka kwe-spindle ngenxa yokudlala; Ukuguga okunamandla kungabangela umonakalo; Amabhawodi esisekelo axegayo; Isivinini sesando siphezulu kakhulu.

Isixazululo: Faka kabusha ama-sando blades ngendlela efanele; Faka esikhundleni isando ukuze uqinisekise ukuthi ukuchezuka kwesisindo sensimbi yesando akudluli ku-5g; Cisha ukuhlola, sebenzisa isando ukuze wenze ucezu olubhayiwe lujikeleze ngokujwayelekile; Faka esikhundleni izingxenye ezilimele ze-turntable futhi uyilinganise; Qondisa noma shintsha i-spindle; Shintsha ama-bearings; Khiya amabhawodi esisekelo ngokuqinile; Yehlisa isivinini sokujikeleza.

2. I-crusher yenza umsindo ongajwayelekile ngesikhathi sokusebenza

Isizathu: Izinto eziqinile njengezinsimbi namatshe zingena ekamelweni elichotshozwayo; Izingxenye ezikhululekile noma ezivaliwe ngaphakathi komshini; Isando saphuka, sawa; Igebe phakathi kwesando nesisefo lincane kakhulu.

Isixazululo: Misa umshini ukuze uhlolwe. Qinisa noma shintsha izingxenye; Susa izinto eziqinile ekamelweni lokuchoboza; Faka esikhundleni isando esaphukile; Lungisa imvume phakathi kwesando nesihlungo. Ukuvunyelwa okufanelekile kokusanhlamvu okujwayelekile kungu-4-8mm, kanti ngotshani kungu-10-14mm.

3. I-bearing is overheated, futhi izinga lokushisa lomshini wokuchoboza we-casing liphezulu kakhulu

Isizathu: Ukuthwala umonakalo noma amafutha okugcoba anganele; Ibhande liqine kakhulu; Ukondla ngokweqile nomsebenzi wesikhathi eside wokugcwala ngokweqile.

Isixazululo: Faka esikhundleni sokuthwala; Engeza amafutha okugcoba; Lungisa ukuqina kwebhande (cindezela phakathi kwebhande lokudlulisela ngesandla sakho ukuze udale ukuphakama kwe-arc kuka-18-25mm); Yehlisa inani lokudla.

4. Umoya ohlanekezelwe endaweni yokuphakela

Isizathu: Ukuvinjwa kwefeni kanye nepayipi lokudlulisa; Ukuvinjelwa kwezimbobo zesisefo; Isikhwama sempushana sigcwele kakhulu noma sincane kakhulu.

Isixazululo: Hlola ukuthi ifeni iguge kakhulu yini; Sula izimbobo zesisefo; Khipha ngesikhathi noma shintsha isikhwama sokuqoqa impushana.

5. Isivinini sokukhipha sehle kakhulu

Isizathu: I-sando blade igugile kakhulu; Ukulayishwa ngokweqile kwe-crusher kubangela ukuthi ibhande lishelele futhi kubangele isivinini esiphansi se-rotor; Ukuvinjelwa kwezimbobo zesisefo; Igebe phakathi kwesando nesisefo likhulu kakhulu; Ukondla okungalingani; Amandla asekelayo anganele.

Isixazululo: Faka esikhundleni isando noma ushintshele kwelinye ikhona; Yehlisa umthwalo futhi ulungise ukungezwani kwebhande; Sula izimbobo zesisefo; Nciphisa igebe phakathi kwesando nesisefo ngokufanele; Ukuphakelwa okufanayo; Shintshanisa injini yamandla aphezulu.

6. Umkhiqizo oqediwe umaholoholo kakhulu

Isizathu: Izimbobo zesisefo zigugile kakhulu noma zonakalisiwe; Izimbobo zemeshi azixhunywanga ngokuqinile esibambi sesisefo.

Isixazululo: Faka esikhundleni se-mesh yesibuko; Lungisa igebe phakathi kwezimbobo zesisefo kanye nesibambi sesisefo ukuze uqinisekise ukulingana okuqinile.

7. Ukushisa kwebhande

Isizathu: Ukuqiniswa okungafanele kwebhande.

Isixazululo: Lungisa ukuqina kwebhande.

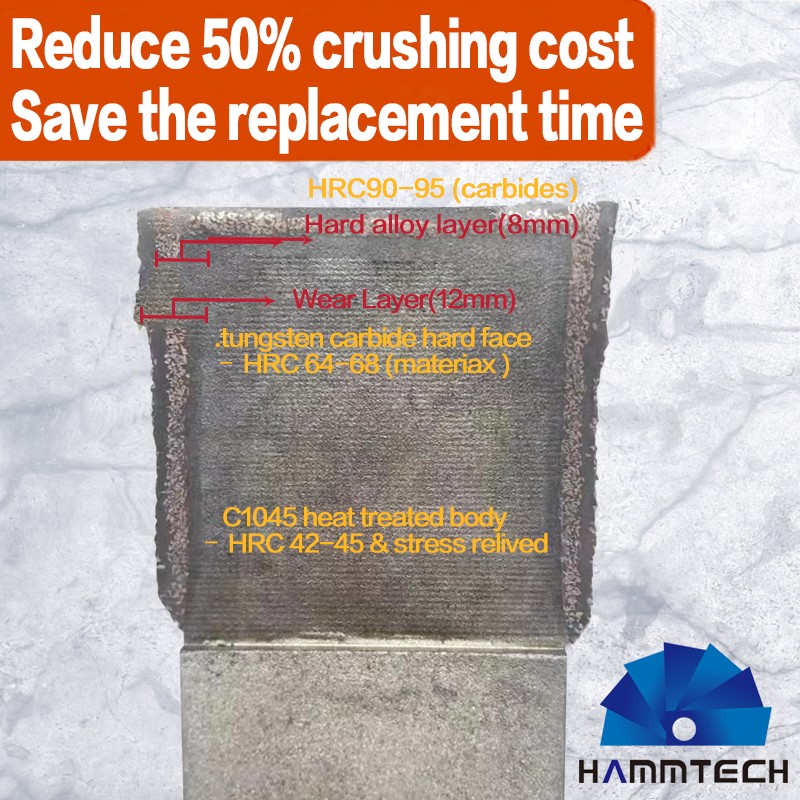

8. Impilo yesevisi ye-hammer blade iba mfushane

Isizathu: Okuqukethwe umswakama okweqile ezintweni kukhulisa amandla nokuqina, okwenza kube nzima kakhulu ukuchoboza; Izinto ezisetshenziswayo azihlanzekile futhi zixutshwe nezinto eziqinile; Igebe phakathi kwesando nesisefo lincane kakhulu; Izinga le-hammer blade liphansi kakhulu.

Isixazululo: Lawula umswakama wempahla ungadluli ku-5%; Nciphisa okuqukethwe ukungcola ezintweni eziningi ngangokunokwenzeka; Lungisa imvume phakathi kwesando nesisefo ngokufanele; Sebenzisa izingcezu zesando ezingagugi zekhwalithi ephezulu, njengezingcezu ezintathu zesando eziphezulu ze-Nai.

Isikhathi sokuthumela: Feb-28-2025