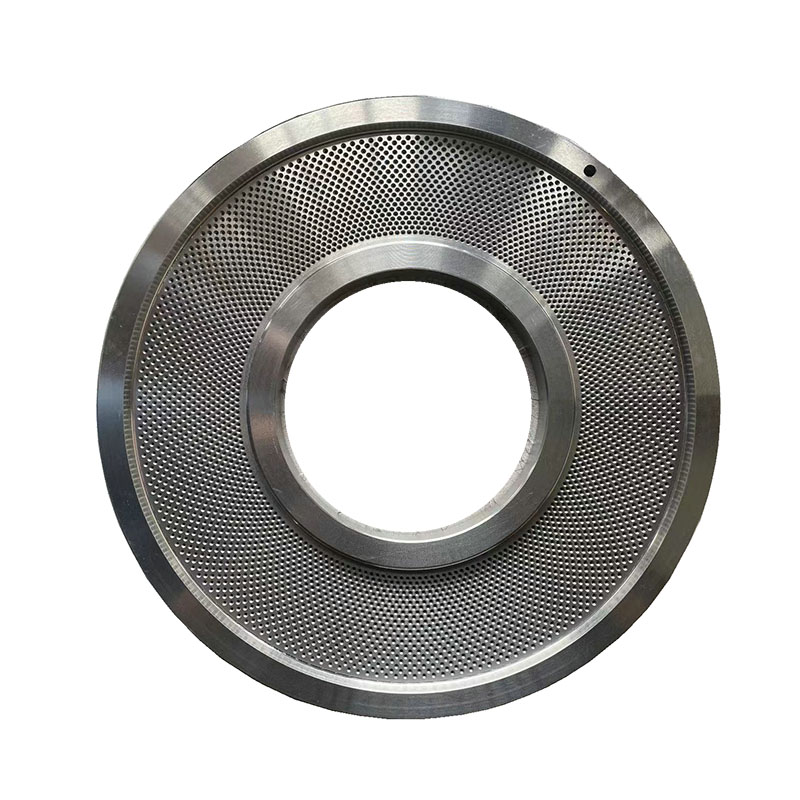

Igobolondo le-Hole Teeth Roller

Igobolondo le-dimpled roller liyingxenye esetshenziswa ekukhiqizeni izigayo ze-pellet, okuyimishini esetshenziselwa ukukhiqiza ama-pellets okudla kwezilwane, ama-biomass pellets, nezinye izinhlobo zamapellets acindezelwe.

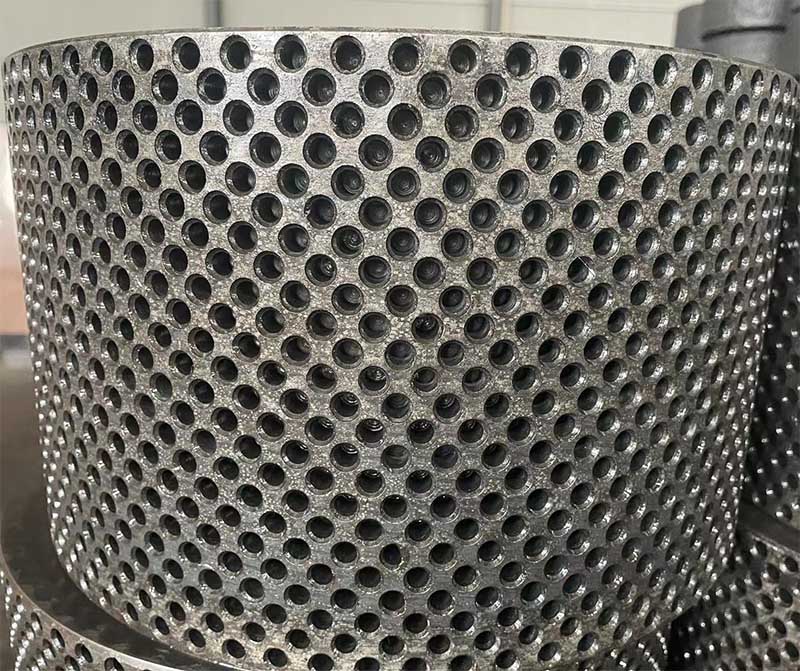

Isici esikhethekile sale shell roller ukutholakala kwama-dimples amancane ebusweni bawo. Ama-dimples asebenza ekwandiseni indawo engaphezulu ye-roller, esiza ukuthuthukisa ikhwalithi yamapellets akhiqizwayo. Ngokwandisa indawo engaphezulu, ama-dimples avumela ukudluliswa kokushisa okungcono ngesikhathi senqubo ye-pelletizing, okungabangela ama-pellets ahambisanayo futhi aphezulu.

Ukusetshenziswa kwamagobolondo e-dimpled roller ezigayweni ze-pellet kungasiza ekuthuthukiseni ukusebenza kahle nokusebenza kwenqubo ye-pelletizing, okuholela kumapellets ekhwalithi ephezulu kanye nokwanda kokukhiqiza.

Ukugcinwa njalo nokuhlolwa kwegobolondo le-roller kufanele kwenziwe ukuze kuqinisekiswe ukuthi lisesimeni esihle sokusebenza. Nazi ezinye izinyathelo okufanele uzilandele ukuze ugcine igobolondo le-pellet mill roller:

1. Hlola igobolondo lamarola ukuze uthole izimpawu zokuguga, ukuqhekeka, noma omunye umonakalo. Uma kukhona umonakalo otholakele, shintsha igobolondo le-roller ngokushesha ukuze uvimbele ukulimala okwengeziwe emshinini wokugaya.

2. Hlanza igobolondo le-roller njalo ukuze uvimbele ukunqwabelana kothuli nemfucumfucu. Sebenzisa ibhulashi noma isiphephetha-moya ukuze ususe noma iyiphi insalela noma izinto zangaphandle ebusweni begobolondo le-roller.

3. Igebe phakathi kwegobolondo le-roller kanye ne-die kufanele lilungiswe njalo ukuze kuqinisekiswe izinga eliphezulu le-pellet nokusebenza kahle kokukhiqiza. Landela imiyalelo yomkhiqizi yokulungisa igebe.

4. Gcoba igobolondo le-roller njalo nge-lubricant yekhwalithi ephezulu. Qiniseka ukuthi ulandela imiyalelo yomkhiqizi yokugcoba.

5. Gwema ukulayisha ngokweqile umshini we-pellet noma ukuwusebenzisa ngesivinini esikhulu, njengoba lokhu kungabangela ukuguga ngokweqile kugobolondo le-roller.

6. Gwema ukusebenzisa izinto eziqhumayo esigayweni se-pellet ngoba lokhu kungabangela ukulimala kwegobolondo le-roller.

7. Ngaso sonke isikhathi landela izincomo zomkhiqizi zokulungisa nokusebenza.